Why Smart Factories are Essential in Today's World

In today's fast-paced manufacturing landscape, the Smart Factory is a vital component for businesses seeking to remain competitive. This guide explores the core technologies driving the Smart Factory revolution, including AI, IoT, and advanced automation. Discover how these technologies can optimize operations, reduce costs, and enhance product quality. We delve into practical applications, real-world examples, and essential implementation strategies to help you build your own Smart Factory. Learn about key components, navigate challenges, and unlock unprecedented efficiency, agility, and profitability in the digital era. Embrace the future of manufacturing and transform your business today.

Introduction: The Dawn of the Smart Factory

The manufacturing sector is undergoing a profound transformation, propelled by rapid technological advancements. The Smart Factory, an integrated ecosystem leveraging technologies like Artificial Intelligence (AI), the Internet of Things (IoT), advanced robotics, and cloud computing, is swiftly becoming the gold standard for efficient and competitive manufacturing. This evolution, often referred to as Industry 4.0, is revolutionizing how products are conceived, designed, manufactured, and delivered to customers.

This comprehensive guide explores why embracing the Smart Factory is not merely an option but an imperative for businesses striving to thrive in today's dynamic and demanding market. We'll delve into the core components, tangible benefits, and practical implementation strategies, providing you with a robust understanding of how to leverage this transformative technology to unlock unprecedented value.

What is a Smart Factory, Really?

A Smart Factory represents a paradigm shift in manufacturing, characterized by a highly digitized and interconnected facility. It harnesses the power of data-driven insights, advanced automation, and cutting-edge technologies to optimize every facet of production processes, dramatically improve operational efficiency, and enhance overall performance. Learn more about the benefits of a smart factory.

Key Components of a Smart Factory

- IoT Sensors and Devices: These ubiquitous sensors collect real-time data from machines, equipment, and processes, providing a granular view of factory operations.

- Data Analytics: Sophisticated analytics platforms analyze the vast amounts of collected data to identify hidden trends, patterns, and anomalies, providing actionable insights for optimization.

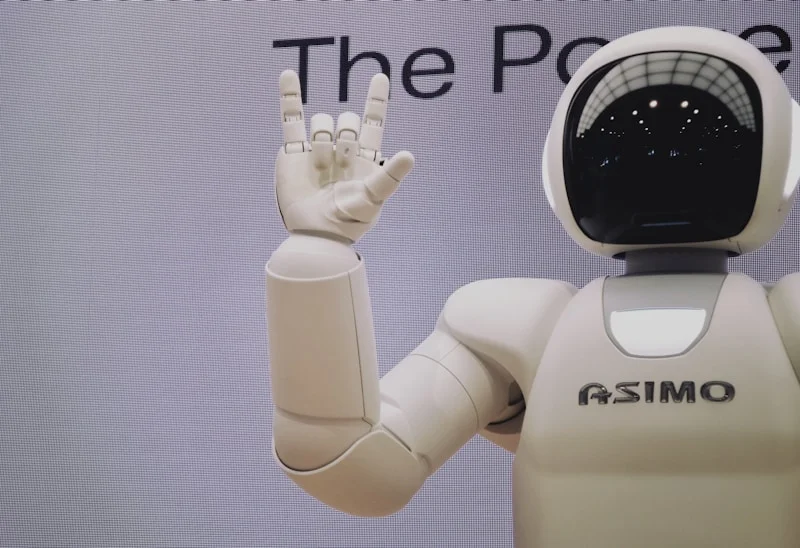

- Automation: Robots, automated systems, and sophisticated software automate repetitive tasks and complex processes, minimizing human error and maximizing throughput.

- Cloud Computing: Secure and scalable cloud infrastructure stores and processes data, enabling accessibility from anywhere and fostering collaboration across teams.

- Artificial Intelligence (AI): AI algorithms enable intelligent decision-making, predictive maintenance, and autonomous optimization of processes, driving continuous improvement.

Why Smart Factories are Indispensable Today

The imperative for Smart Factories stems from a confluence of pressing challenges and unprecedented opportunities in the modern manufacturing landscape. These include intensifying global competition, ever-rising customer expectations, and the relentless pursuit of greater operational efficiency and sustainability.

Here's a detailed breakdown of the key reasons why Smart Factories are no longer optional but indispensable for future success:

Unleashing Unprecedented Efficiency and Productivity

Smart Factories meticulously optimize production processes, drastically reduce waste, and dramatically improve overall efficiency. Automation minimizes the potential for human error and enables significantly faster production cycles. This translates to higher output, shorter lead times, and increased profitability.

Real-time data analysis provides invaluable insights into bottlenecks, inefficiencies, and areas for improvement, empowering manufacturers to make data-driven decisions and continuously improve productivity. Learn how this improves product quality.

Slashing Costs and Maximizing Resource Utilization

By automating labor-intensive tasks, optimizing resource utilization across the board, and minimizing costly downtime, Smart Factories significantly lower operational costs. Predictive maintenance, powered by AI, helps prevent catastrophic equipment failures and extends the lifespan of critical machinery. This dramatically reduces maintenance costs and improves overall profitability, contributing to a healthier bottom line.

Furthermore, efficient supply chain management, facilitated by IoT sensors and advanced data analytics, minimizes inventory costs, optimizes logistics, and ensures the timely delivery of essential materials. Lean manufacturing principles are greatly enhanced and accelerated by the implementation of Smart Factory technologies.

Elevating Quality and Ensuring Consistency

Smart Factories ensure consistent product quality through the implementation of automated monitoring and precision control systems. Real-time data analysis helps identify and address potential quality issues early in the production process, preventing defects from propagating downstream.

This proactive approach results in fewer defects, reduced waste, and significantly higher customer satisfaction. Consistent quality is a key differentiator in today's hyper-competitive global market.

Enhancing Agility and Fostering Flexibility

Smart Factories are inherently adaptable and can rapidly respond to evolving customer demands, shifting market conditions, and unexpected disruptions. Flexible manufacturing systems allow for easy customization and the production of diverse product variations with minimal downtime.

This enhanced agility empowers manufacturers to capitalize on emerging opportunities, maintain a competitive edge, and thrive in a rapidly changing world. Discover how to implement a Smart Factory.

Empowering Data-Driven Decision-Making

Data-driven insights empower manufacturers to make informed decisions based on real-time information, rather than relying on intuition or guesswork. Predictive analytics helps forecast future trends, anticipate potential problems, and optimize resource allocation.

This proactive approach allows for better resource allocation, improved risk management, and more effective strategic planning. Data is the new oil in the manufacturing sector, and Smart Factories are equipped to extract maximum value from it.

Implementing a Smart Factory: Key Considerations for Success

Implementing a Smart Factory requires meticulous planning, a strategic approach, and a clear understanding of your organization's specific needs and goals. It's essential to carefully consider the following critical factors:

Assessing Current Infrastructure and Identifying Gaps

Conduct a thorough evaluation of your existing infrastructure, including hardware, software, network connectivity, and security protocols. Identify areas that require upgrades, modifications, or replacements to effectively support Smart Factory technologies.

Choosing the Right Technologies for Your Needs

Select the technologies that best align with your specific needs, objectives, and budget. Consider factors such as cost, scalability, compatibility with existing systems, and the level of technical expertise required for implementation and maintenance.

Developing a Robust Data Management Strategy

Establish a comprehensive data management strategy to ensure data quality, security, accessibility, and compliance with relevant regulations. This strategy should encompass data collection, storage, processing, analysis, and visualization.

Investing in Training and Upskilling Employees

Provide comprehensive training and upskilling opportunities for employees to adapt to new technologies, processes, and roles within the Smart Factory environment. This investment will ensure that your workforce is equipped to leverage the full potential of these advanced systems.

Prioritizing Cybersecurity and Data Protection

Implement robust cybersecurity measures to protect your Smart Factory from cyber threats, data breaches, and intellectual property theft. Cybersecurity is paramount in a connected environment, and a proactive approach is essential.

Real-World Examples of Smart Factory Implementation

Numerous companies have successfully implemented Smart Factory technologies and achieved remarkable results, demonstrating the tangible benefits of this transformative approach.

Consider these illustrative examples:

- Siemens: Siemens leverages digital twins to simulate and optimize production processes, reducing waste, improving efficiency, and accelerating time-to-market.

- BMW: BMW employs advanced robots and automation to enhance efficiency, improve quality, and increase flexibility in its automotive manufacturing plants.

- Procter & Gamble: Procter & Gamble leverages data analytics to optimize supply chain management, reduce waste, and improve overall operational efficiency across its global network of manufacturing facilities.

FAQ: Demystifying Smart Factories

What are the primary benefits of adopting a Smart Factory?

The key benefits include increased efficiency, reduced costs, improved quality, enhanced agility, better decision-making, and improved sustainability.

What is the typical cost of implementing a Smart Factory?

The cost varies significantly depending on the scale of the implementation, the specific technologies used, and the complexity of existing infrastructure. A pilot project can start small and scale up incrementally.

What skills are essential for working in a Smart Factory?

Skills in data analytics, automation, AI, robotics, cybersecurity, and IT infrastructure are highly valuable in a Smart Factory environment.

How can small and medium-sized enterprises (SMEs) benefit from Smart Factories?

SMEs can benefit from improved efficiency, reduced costs, enhanced competitiveness, and increased agility by adopting Smart Factory technologies on a smaller scale and focusing on specific areas of improvement.

What are the potential challenges associated with implementing a Smart Factory?

Potential challenges include high initial investment costs, cybersecurity risks, the need for employee training and upskilling, integration complexities, and data privacy concerns.

Call to Action: Embrace the Future of Manufacturing

Ready to transform your manufacturing operations and embrace the future of manufacturing? Contact us today to learn how our Smart Factory solutions can help you achieve your business goals and unlock unprecedented value.

Don't get left behind in the digital revolution. Embrace the Smart Factory revolution today and secure your future success!

Conclusion: The Future of Manufacturing is Smart

The Smart Factory is no longer a futuristic concept but a critical necessity for manufacturers seeking to thrive in today's competitive landscape. By embracing automation, data analytics, and AI, businesses can unlock significant benefits, including increased efficiency, reduced costs, improved quality, and enhanced agility.

The future of manufacturing is undoubtedly smart, and companies that proactively invest in Smart Factory technologies will be well-positioned for long-term success and sustainable growth.

Share this article

Admin User

Content Author

Related Articles

HOT

HOT

HOT

HOT