AI in Manufacturing: Transforming Thai Factories in 2025

Discover how artificial intelligence is revolutionizing Thai manufacturing industry with smart factory solutions and predictive maintenance.

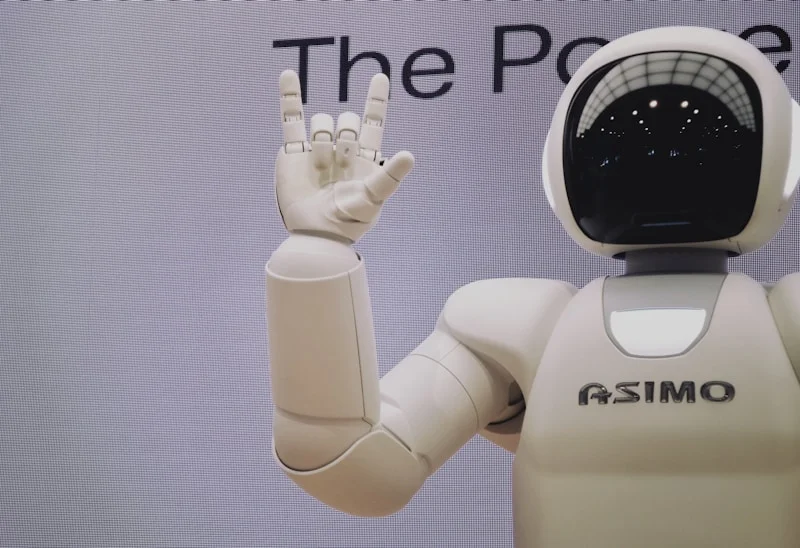

# AI in Manufacturing: Transforming Thai Factories in 2025 Artificial Intelligence (AI) is revolutionizing the manufacturing landscape in Thailand. As we move through 2025, Thai factories are increasingly adopting AI-powered solutions to enhance productivity, reduce costs, and maintain competitive advantages in the global market. ## The Current State of AI in Thai Manufacturing Thailand manufacturing sector has seen significant AI adoption, with over 60% of medium to large factories implementing at least one AI-powered system. This transformation is driven by several factors: 1. **Government Support**: Thailand 4.0 initiative promotes digital transformation 2. **Cost Reduction**: AI reduces operational costs by 30-50% 3. **Quality Improvement**: Automated quality control catches defects early 4. **Workforce Evolution**: Workers upskill to manage AI systems ## Key AI Applications in Factories ### 1. Predictive Maintenance AI algorithms analyze equipment data to predict failures before they occur, reducing downtime by up to 40%. Sensors monitor: - Vibration patterns - Temperature fluctuations - Energy consumption - Performance metrics ### 2. Quality Control Computer vision systems inspect products at speeds impossible for human workers, achieving: - 99.9% accuracy rates - Real-time defect detection - Reduced waste by 25% - Consistent quality standards ### 3. Production Optimization Machine learning models optimize production schedules, inventory levels, and resource allocation: - 20% increase in production efficiency - Reduced inventory costs by 30% - Better demand forecasting - Energy consumption optimization ## Case Study: Smart Factory 360?? Implementation A mid-sized automotive parts manufacturer in Rayong implemented our Smart Factory 360?? solution: **Before Implementation:** - Manual quality inspections - Reactive maintenance - 15% defect rate - Frequent unexpected downtime **After Implementation (6 months):** - Automated quality control - Predictive maintenance - 2% defect rate - 95% reduction in unplanned downtime - ROI achieved in 14 months ## Challenges and Solutions ### Challenge 1: Initial Investment **Solution**: Cloud-based subscription models (OpEx) eliminate large upfront costs. ### Challenge 2: Skills Gap **Solution**: Comprehensive training programs and ongoing support. ### Challenge 3: Integration **Solution**: Modular systems that work with existing infrastructure. ## Future Trends 1. **Edge AI**: Processing data at the source for faster decisions 2. **Digital Twins**: Virtual factory simulations for optimization 3. **Collaborative Robots**: AI-powered robots working alongside humans 4. **5G Integration**: Ultra-fast connectivity for real-time monitoring ## Getting Started with AI in Your Factory 1. **Assessment**: Evaluate current processes and pain points 2. **Pilot Project**: Start small with one production line 3. **Measure Results**: Track KPIs and ROI 4. **Scale Up**: Expand successful implementations 5. **Continuous Improvement**: Regular updates and optimization ## Conclusion AI is no longer a future technology???it is transforming Thai factories today. Companies that embrace AI-powered manufacturing will gain significant competitive advantages in efficiency, quality, and cost management. Ready to transform your factory with AI? Contact KTNBS for a free consultation and see how Smart Factory 360?? can revolutionize your operations. --- **Keywords**: AI manufacturing Thailand, smart factory, predictive maintenance, Industry 4.0, factory automation, Thai manufacturing

Share this article

Admin User

Content Author

Related Articles

HOT

HOT